Higher VET Course in Mechanical Manufacture Design

Higher technicians in mechanical manufacturing design acquire the personal and technical skills to devise and develop solutions for mechanical projects in the industrial sector.

Duration and language

2.000 hours (2 courses)

Model D

Schedule

Monday to Thursday: 8:00 – 14:45

Friday: 8:00 – 14:00

Access condition

High School, Basic VET, Higher VET Course or test for those over 20 years of age

> The ETHAZI learning methodology.

> Profile with critical and creative thinking to devise innovative solutions.

> Profile with a high level of practical knowledge and versatility.

> Good employability. Industrial environment.

> Use of cutting-edge technological resources.

In the Higher Vocational Education Training Course in Mechanical Manufacture Design, we aim to prepare people and professionals in all the skills required to design constructive solutions for mechanical products and tools for various industrial sectors with high employability. At the end of the course, students will be able to enter the labour market directly or continue their academic career by taking another higher training course, a specialisation programme or a university degree.

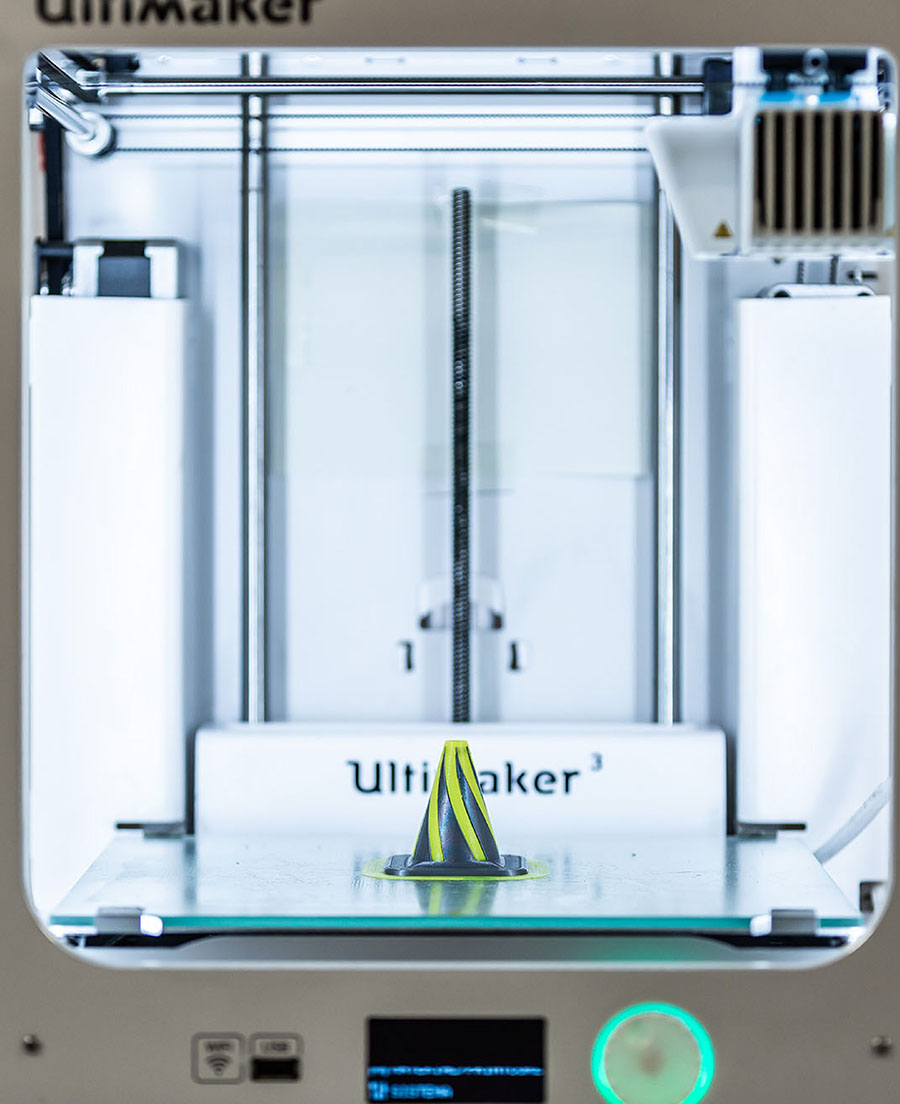

The equipment and technology that students will experience first-hand at Politeknika Txorierri include:

The professional modules of this course are the following:

Mechanical Manufacturing Products

In this training course you will learn to design mechanical manufacturing products, sheet metal processing tools, moulds and models for polymers, casting, forging, stamping or powder metallurgy, ensuring quality and complying with occupational risk prevention and environmental protection regulations.

Transversal competences through ETHAZI methodology

At Politeknika Txorierri we work using the ETHAZI methodology in which the student, in addition to acquiring the technical competences that he/she must obtain, achieves other transversal competences that will help him/her in his/her professional career.

That is, teamwork, communication, involvement, initiative, responsibility…. To this end, we work in the classroom through real-life based challenges.

ACADEMIC CHALLLENGES

- Gearbox Challenge: Cross-modular challenge whose objective is to carry out calculations, define specifications, design and manufacture the constructive solution, assemble and start up a gearbox according to the initial requirements.

- Stamping Tooling Challenge: Modular challenge whose objective is to carry out the technical-economic study, the design of the tooling and the technical information necessary to obtain a sheet metal part by stamping.

LEARNING CHALLENGES

- Functional Diversity Challenge: Challenge in collaboration with an association, whose objective is to analyse the real need of a person with functional diversity, instilling the importance of 4.0 values in society, designing and manufacturing a 3D prototype of the technical solution.

- Basuraleza Challenge: Challenge in collaboration with an association, the aim of which is to analyse the collection of existing waste in aquatic environments, instilling the importance of environmental sustainability, designing and manufacturing a 3D printing prototype of the technical solution.

CHALLENGES FOR COMPANIES

- Reverse Engineering Challenge: An industrial SME company asks students to digitise a physical part using an optical scanner and obtain the ruled geometry in order to improve or redesign the part. Subsequently, the analysis of the topological optimisation of the part, manufacturing process, etc. is carried out…

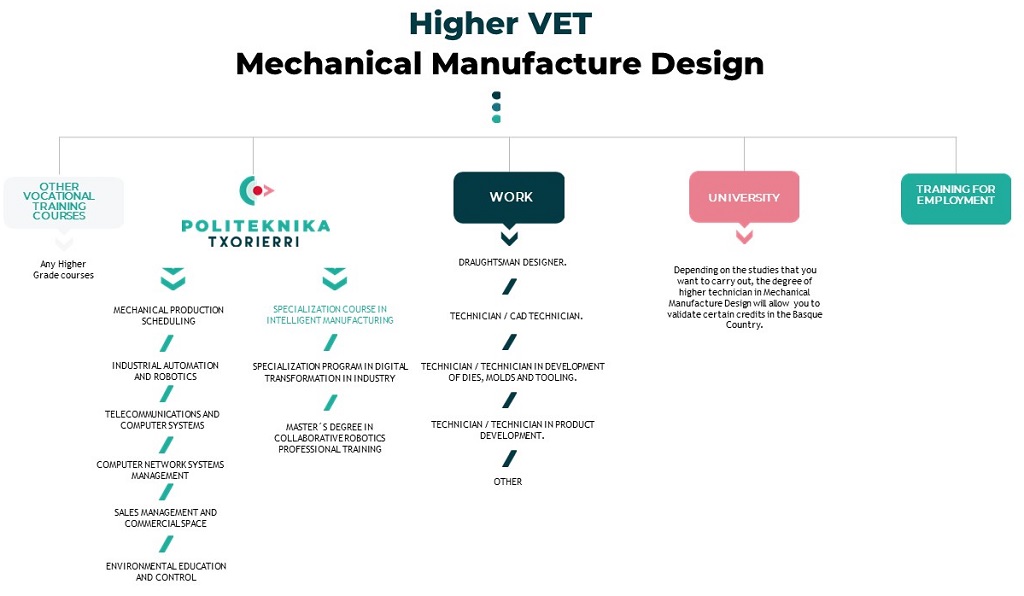

And then what?

What are the options after completing the Higher Vocational Training Course in Mechanical Manufacturing Design?