Higher VET Courses in Industrial Automation and Robotics

Higher technicians in industrial automation and robotics acquire the competences to become a competent professional in industry 4.0 where solutions to technical projects in the fields of electricity and electronics are developed.

Duration and language

2.000 hours (2 courses)

Model D

Schedule

Monday to Thursday: 8:00 – 14:45

Fruday: 8:00 – 14:00

Access condition

High School, Basic VET, Higher VET Course or test for those over 20 years of age.

> ETHAZI collaborative work methodology and personalised monitoring by the teaching staff.

> Use of innovative technologies implemented in the most cutting-edge companies.

> High practical component oriented towards solving real problems.

> The teaching staff has a close relationship with the surrounding business network.

> Very high employability index.

> Possibility of Dual Training.

The growing demand of an increasingly technological and globalised market requires professionals with a training profile that is proficient in technology, which is necessary in most areas of work. This means that there is a great need in the labour market for technical equipment in the fields of electricity and electronics.

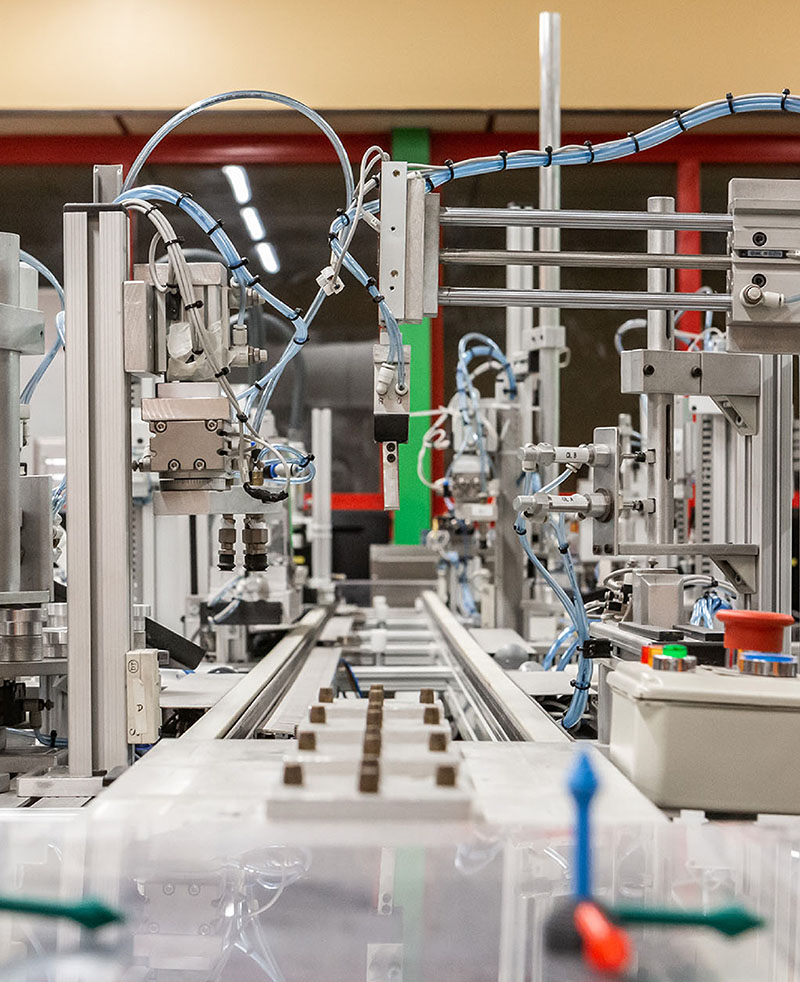

The equipment and technology that students will experience first-hand at Politeknika Txorierri include:

The professional modules of this course are the following:

Electrical, pneumatic and hydraulic systems

With the higher course in industrial automation and robotics, you will quickly gain solid knowledge in electrical, pneumatic and hydraulic systems, programmable logic controllers, industrial and collaborative robotics.

Transversal competences through ETHAZI methodology

At Politeknika Txorierri we work using the ETHAZI methodology in which the student, in addition to acquiring the technical competences that he/she must obtain, achieves other transversal competences that will help him/her in his/her professional career.

That is, teamwork, communication, involvement, initiative, responsibility…. To this end, we work in the classroom through real-life based challenges.

ACADEMIC CHALLENGES

- Flexible cell: in this challenge we set up a flexible production system made up of different independent workstations that must be programmed to work in a coordinated way, so that the parts arrive at the end of the production line after a series of operations have been carried out on them. At the end of the process, the robot picks up the processed part and places it in its storage position.

LEARNING CHALLENGES

- Gyroscope for wheelchairs: in this challenge we designed and assembled a microcontroller with a gyroscope to measure the position of a wheelchair, so that if the chair loses its horizontality the system sends a message to the person responsible. This service will be used to detect falls of wheelchair users.

- Smart furniture: in this challenge we designed a system based on a microcontroller and motors to move different elements of the furniture (opening doors and drawers of a wardrobe, adjusting the height of a table…) so that users with difficulties can access them.

CHALLENGES FOR COMPANIES

- Intelligent warehouse: In this challenge we simulate any pick & place process with a robot, both collaborative and industrial, that can satisfy the demand of any company in the environment…

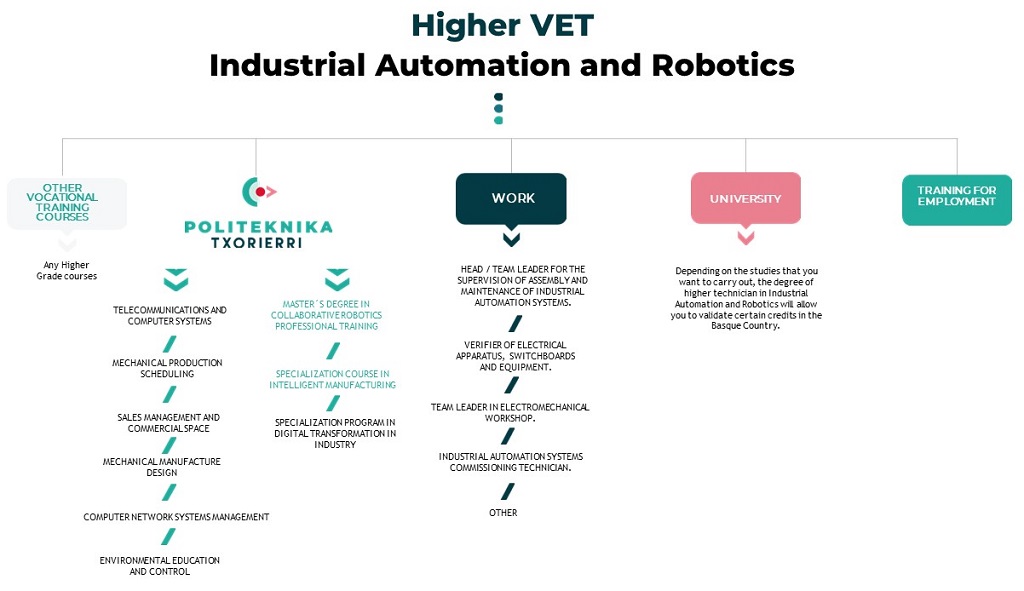

And then what?

What are the options after completing the Higher Vocational Training Course in Industrial Automation and Robotics?