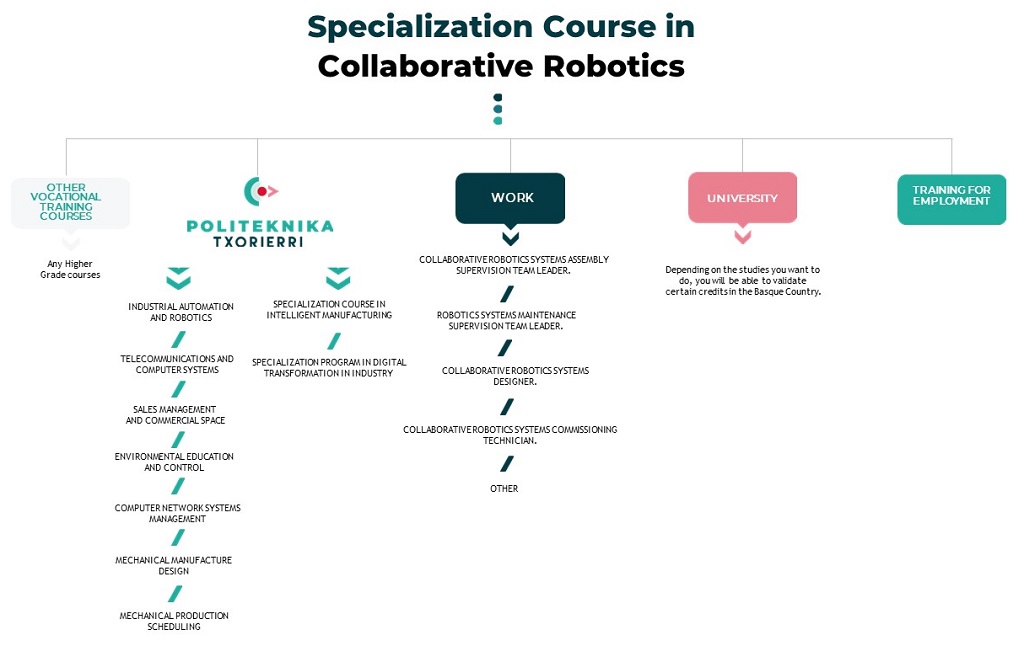

Specialisation Course in Collaborative Robotics

The current labour market demands professionals capable of managing the means used in highly automated production systems within the industrial sector, executing the different production and maintenance tasks under the company’s own methodological standards, always complying with the rules and plans for the prevention of occupational and environmental risks.

Language

Model D

Timetable

8:00 – 14:00

Entry requirements

Higher VET Course, work experience or knowledge in the area.

> DUAL methodology.

> ETHAZI collaborative work methodology and personalised monitoring by the teaching staff.

> Use of innovative technologies and implementation in the most cutting-edge companies.

> High practical component oriented towards solving real problems.

> The teaching staff has a close relationship with the surrounding business network.

With the Specialization course in Collaborative Robotics, you will delve deeper into the technologies of Industry 4.0.

The equipment and technology that students will use at Politeknika Txorierri will be:

The professional modules of this training course are the following:

Collaborative Robotics

In the Specialisation course in Collaborative Robotics, you will gain advanced knowledge in collaborative robotic systems, both with anthropomorphic arms and mobile vehicles (AGV / AMR).

Transversal competences through the ETHAZI methodology

We work using the ETHAZI methodology in which students, in addition to acquiring the technical skills they need to obtain, acquire other transversal skills that will help them in their professional career. That is, teamwork, communication, involvement, initiative, responsibility ….

ACADEMIN CHALLENGES

- Flexible cell: in this challenge we set up a flexible production system made up of different independent workstations that must be programmed to work in a coordinated way, so that the parts arrive at the end of the production line after a series of operations have been carried out on them. At the end of the process, the robot picks up the processed part and places it in its storage position.

LEARNING CHALLENGES

- Gyroscope for wheelchairs: in this challenge we designed and assembled a microcontroller with a gyroscope to measure the position of a wheelchair, so that if the chair loses its horizontality the system sends a message to the person responsible. This service will be used to detect falls of wheelchair users.

- Smart furniture: in this challenge we designed a system based on a microcontroller and motors to move different elements of the furniture (opening doors and drawers of a wardrobe, adjusting the height of a table…) so that users with difficulties can access them.

CHALLENGES FOR COMPANIES

- Intelligent warehouse: In this challenge we simulate any pick & place process with a robot, both collaborative and industrial, that can satisfy the demand of any company in the environment.