Higher VET Course in Mechanical Production Scheduling

Higher Technicians in Mechanical Production Scheduling acquire the personal and technical competences necessary to carry out the tasks of planning, scheduling and control of the manufacture and assembly of products in the industrial sector.

Duration and language

2.000 hours (2 courses)

Model D

Schedule

Monday to Thursday: 8:00 – 14:45

Friday: 8:00 – 14:00

Access condition

High School, Basic VET, Higher VET Course or test for those over 20 years of age.

> ETHAZI learning methodology..

> High employability. Industrial environment.

> Multi-purpose professional profile in industry.

> High demand from companies for Dual Training.

> Use of cutting-edge technological resources.

In the Higher VET training course in Mechanical Production Scheduling, we aim to prepare people and professionals in all the skills required for middle management and production managers in an industrial sector with a high level of employability. At the end of the course, students will be able to enter the labour market directly or continue their academic career by taking an advanced training course.

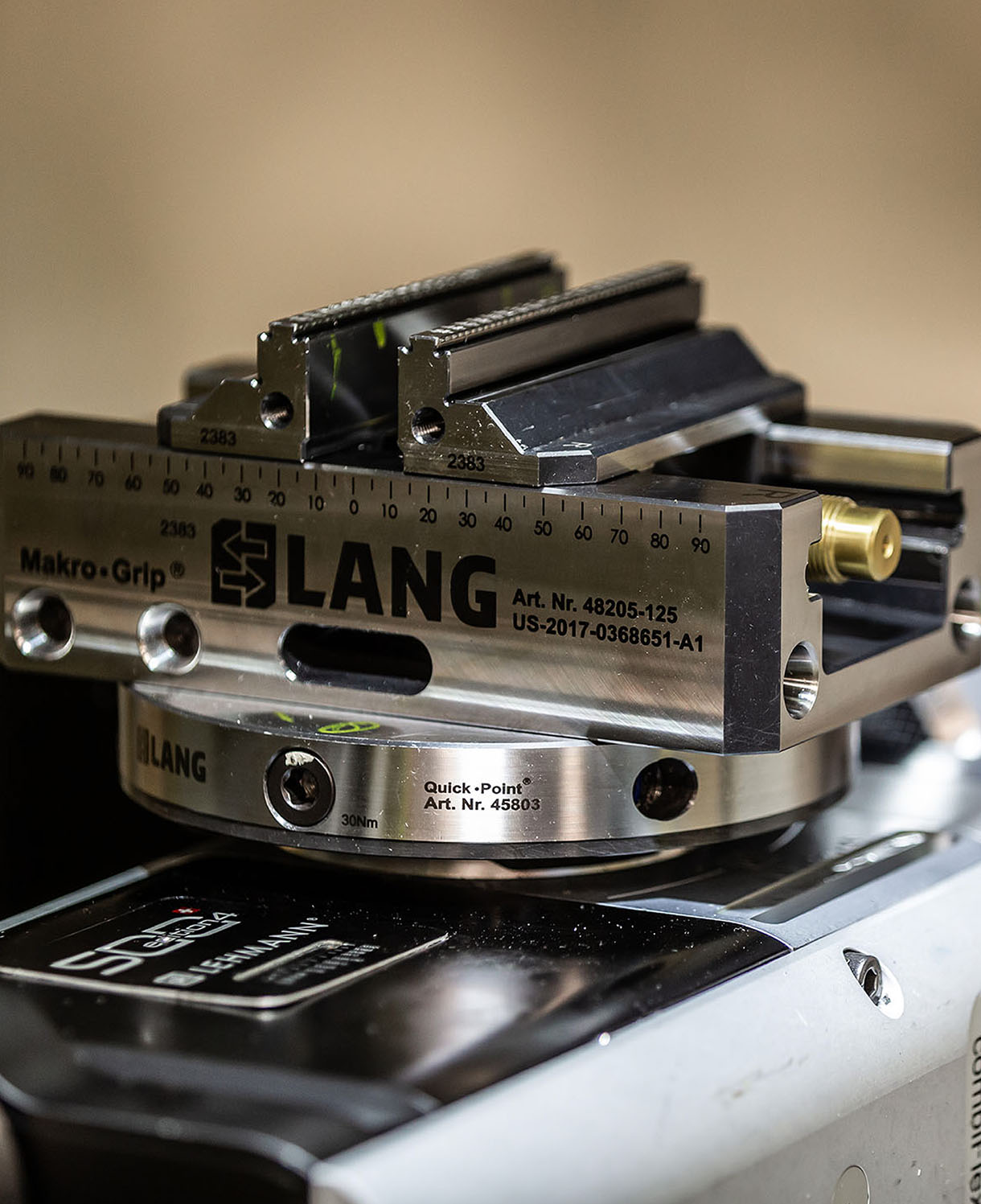

The equipment and technology that students will experience first-hand at Politeknika Txorierri include:

The professional modules of this course are the following:

Planing, programming and programming control

In this training course you will learn to plan, programme and control the machining and assembly of capital goods, based on the documentation of the process and the specifications of the products to be manufactured, ensuring the quality of the management and products, as well as the supervision of the systems for the prevention of occupational hazards and environmental protection.

Transversal competences through ETHAZI methodology

At Politeknika Txorierri we work using the ETHAZI methodology in which the student, in addition to acquiring the technical competences that he/she must obtain, achieves other transversal competences that will help him/her in his/her professional career.

That is, teamwork, communication, involvement, initiative, responsibility…. To this end, we work in the classroom through real-life based challenges.

ACADEMINC CHALLENGES

- CAM Challenge: Cross-modular challenge, the objective of which is the study and programming of parts using CAM (Computer Aided Manufacturing) and launching and execution on CNC (Computer Numerical Control) machines.

- Part Inspection Challenge: Cross-modular challenge, whose objective, after the manufacture of a part with complex geometry, is to carry out the dimensional and geometric verification of the part obtained with respect to the reference or CAD part by means of CMM and optical scanner and the analysis of the results.

LEARNING CHALLENGES

- Functional Diversity Challenge: Challenge in collaboration with an association, the objective of which is the analysis, definition and execution of a real technical solution for a person with functional diversity with a need.

- Rubbish Challenge: Challenge in collaboration with an association, the objective of which is to devise constructive solutions whose manufacture must be obtained by a chip removal process for the collection of existing rubbish in aquatic environments.

CHALLENGES FOR COMPANIES

- Production Programming Challenge: An industrial SME company asked students to prepare a real challenge with the general objective of carrying out the study and serial manufacturing of a part. The students have carried out the manufacturing study of the different machining phases, cutting conditions and the manufacturing times necessary to carry out each individual part. Subsequently, they have defined the internal production programming and have carried out the manufacture of a small series of parts to evaluate the results.

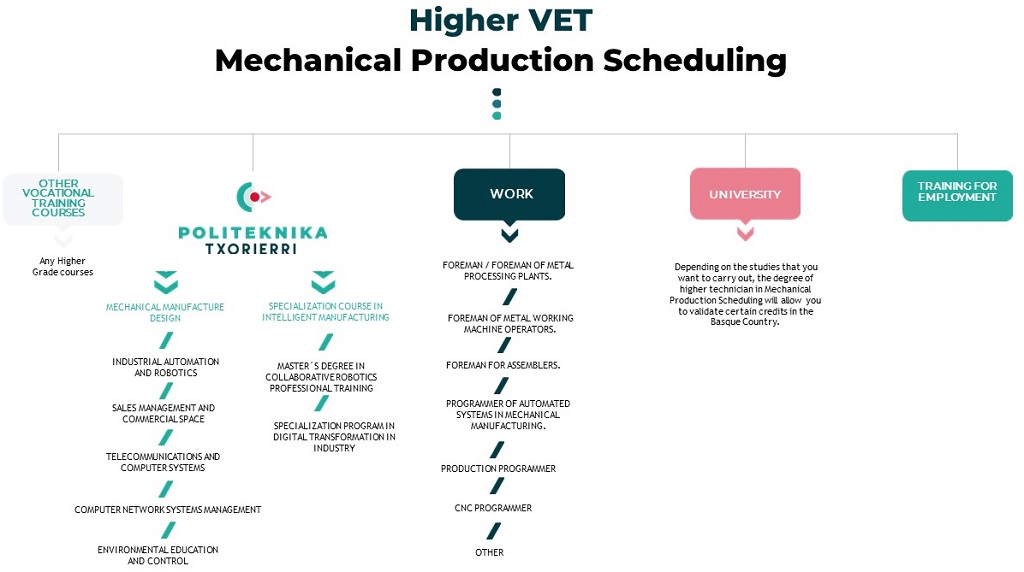

And then what?

What are the options after completing the Higher Vocational Education Training Course in Mechanical Production Scheduling?